FAE Soil Stabilisation Drums

Soil Stabilisation Machinery.

FAE are offering a comprehensive range of soil stabilisation machinery. Many unique and market leading features are therefore placing these machines at the forefront of soil stabilisation machinery.

The long established FAE variable chamber philosophy and the hybrid crusher stabiliser drums of the Multi Task models are presenting operators with real world performance advantages. Especially so with increasingly varying and often challenging site conditions.

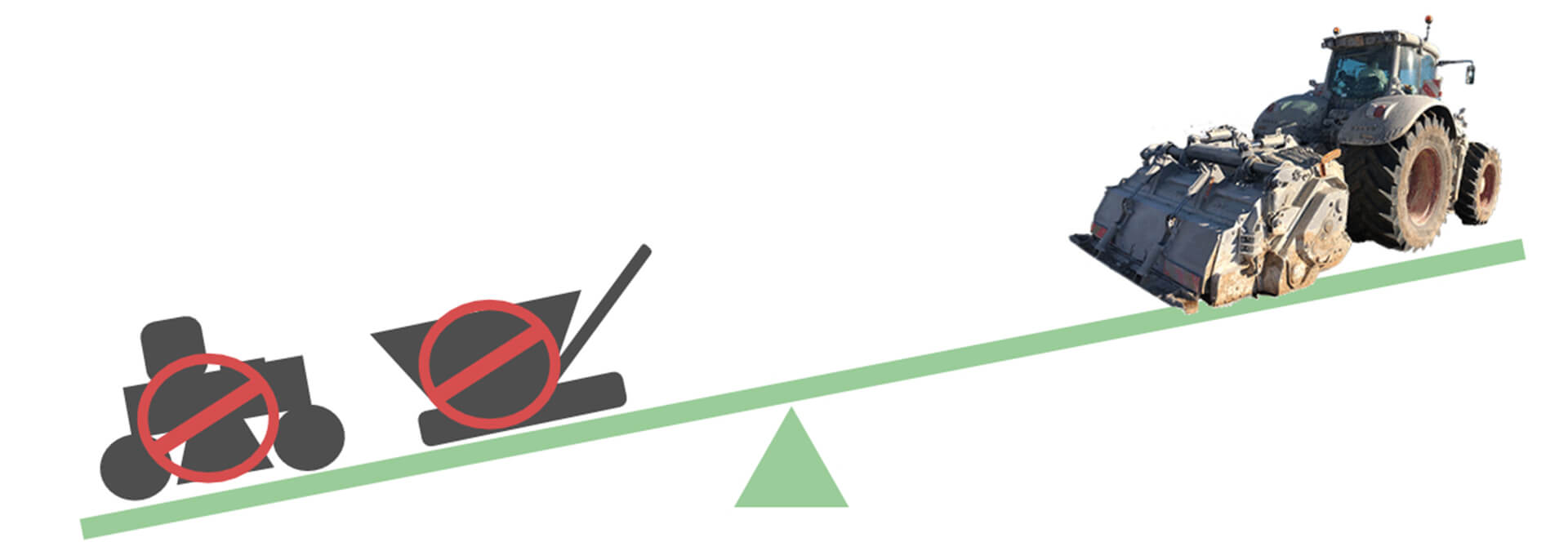

Harnessing the Performance of a Dedicated unit with the Versatility of a Tractor Mounted Machine.

- Dedicated performance with tractor mounted versatility and capital expenditure

- Eliminate the separate operation of oversize crushing

- Reduce daily maintenance and spares and repair costs

- High output with use of modern 500hp tractors

- Eliminate power hungry hydrostatic transmissions

Soil Stabilisation Attachments

These Soil Stabilisation Drums effectively incorporate binders to improve or stabilise the soils and other unsuitable materials.

This is reliant on the pulverisation of soils and materials which ensures thorough mixing. The FAE stabilisation drum range uniquely includes many professional features. The multitask machines can crush rock and stones without compromise and also undertake simple mixing duties. This sets these machines apart as being adapted to the conditions contractors encounter.

FAE Stabilisation drums can be found operating in:

FAE Stabilisation drums can be found operating in:

- Soil Stabilisation

- Asphalt Recycling

- Stone Crushing

- Road and Track Recycling

Cost and Environmental Benefits

Offering significant cost and environmental benefits the stabilising of soils is now a widely adopted process used on many construction projects. Additionally benefits in timing when compared to traditional Muck away and stone replacement helps to keep projects on track.

Soil Stabilisation is a term used to describe treating materials with lime, cement and many other binders to achieve enhanced material properties for use in construction projects.

Drying soils

Drying soils

Drying soils with lime or stabilising soils by adding cement or other binders into a granular material for onward use as a stone replacement layer.

FAE have developed a range of machinery for use within the construction market. The FAE machinery is unique in so far as they are designed to be able to handle both the toughest site conditions and harness the largest of tractors to provide huge work rates.

Stabilising of rocky soils.

It is rare for sites to present only the best of materials and often heavy clays are inter mixed with rocks and stones. This is especially true with brown field sites and when working on regeneration projects.

The FAE Soil Stabilisation machinery ranges are designed to offer operators a cost effective professional solution utilising modern high horse power tractors. Doing this while not compromising the overall output or quality of production is what these FAE machines are designed for.

Ashphalt Recycling

A high density of tools and large diameter drums means the Multi Task range are efficient road recycling units.

A high density of tools and large diameter drums means the Multi Task range are efficient road recycling units.

High torque drive lines sees optimal drum speeds for operating without excessive heat or tool impacts.

FAE Heavy duty transmissions with large, strong gearboxes ensure the machines cope with the hardest of work, the largest of tractors and the very highest of outputs.

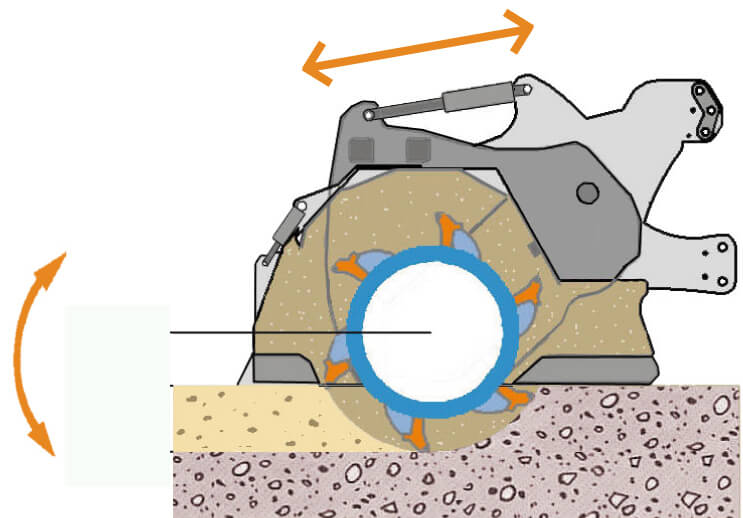

The drum drops from beneath the frame to provide accurate depth control and also regulates the recycling quality and performance.

Contact us to discuss how the FAE range can offer cost effective recycling to the highest standards.

Forest Roads - Stone Crushing

The efficient and rugged crushing action of the Multi task range doesn't mean there is compromise on crushing power.

The efficient and rugged crushing action of the Multi task range doesn't mean there is compromise on crushing power.

Large diameter drums featuring the unique FAE tooling systems along with hardox protection plates means the Multitasks are as happy at work on a forest road project as working on a clay stabilisation job.

The rugged build and versatility means that traditional unbound roads - which rely on the correct material gradings are easily produced. An adjustable anvil and rear grid allow effective control of material production.

Where binder is to be introduced the range excels with the proven ability to incorporate and pulverise. The in drum water injection system furthermore allows accurate control of the hydration of binders or addition of water to assist compaction.

Tractor Mounted Grader Blades

When using a Crusher for road and trackways our tractor mounted grader provides a camber quickly. Find out more on our Grader page.

Brown Field Remediation

Working on brown sites creates headaches especially with contamination from previous site uses or inadequate demolition practices.

Working on brown sites creates headaches especially with contamination from previous site uses or inadequate demolition practices.

Traditional stabilisers have long suffered damage from oversize concrete, rocks and stones. The Crushing action of the FAE Multitasks means you need no longer suffer excessive daily maintenance or even more severe drum damage.

The FAE tooling system has not only a high density of tools but these are mounted into durable drum sockets which are designed to sustain high impacts.

Costs incurred with downtime, repairs and wear part consumption are now reduced with oversize material crushed within the acceptable matrix for layer compaction. With the FAE multi task range you have the assurance of knowing that you have a site solution for every site - in 1 machine.

Water Injection Directly Into The Chamber

Water is applied through nozzles directly into the mixing chamber. A choice of control systems allows the option for full computer controlling of application rates in proportion to working depth and forward speed.

Water is applied through nozzles directly into the mixing chamber. A choice of control systems allows the option for full computer controlling of application rates in proportion to working depth and forward speed.

Alternatively a simple to use control systems allows operators to determine the volumes of water needed to ensure optimum water content for the production of end materials.

East assembly of nozzles is making maintenance a simple affair and ensures reliable operation on site.

Machine Tooling

FAE are offering a number of optional tool choices on the stabiliser and hybrid crusher drums.

Typical round shank picks as seen for decades are offered right through to the modern heavy duty carbide tooling systems.

These heavy tools are offering outstanding performance even in heavy stoney and rock conditions and are eliminating many hours of maintenance - increasing outputs and saving customers money.

The tools are mounted within sockets in the drum. The Multitask tooling system has integral holder systems and the round shanks are mounted into a simple holder base.

All tools are changed by screw and avoids the heavy maintenance burden of cutting and replacing of common old fashioned welded holders.

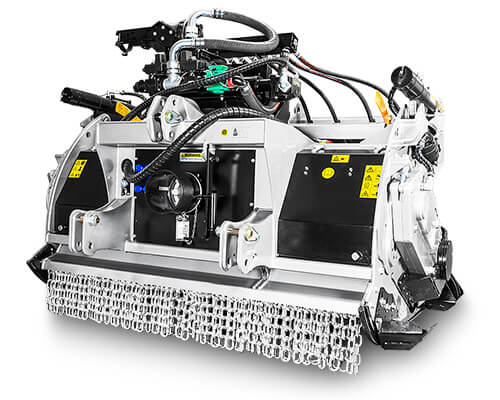

Heavy Duty Drive

The heavy duty engineering featuring in the FAE range of Soil Stabilisers and Hybrid Crusher Stabilisers ensures even the largest of tractors are harnessed reliably.

The Hybrid drums feature large gearboxes with oil circulation and cooling circuits which cope with the largest of the tractors giving long term productivity. The Stabi range of attachments are transmitting power through large power bands. The power is turned into rugged rotating power through integral epicyclic gearboxes housed within the drums.

The efficient power transmission of the latest generation of tractors results in power delivery to the attachments avoiding any inefficient hydrostatic drive systems. This means the attachments are built strong to provide both output and reliability.

Internal Wear Plates

The original design concept of the Hybrid Drums was always that they must be able to cope with the abrasive conditions with crushing and processing large volumes of material. The drum and tooling are one half of the equation with readily changed tooling. It is equally important that the frame of the machine must also be protected to ensure a long productive life.

The original design concept of the Hybrid Drums was always that they must be able to cope with the abrasive conditions with crushing and processing large volumes of material. The drum and tooling are one half of the equation with readily changed tooling. It is equally important that the frame of the machine must also be protected to ensure a long productive life.

The internal wear plates are all changeable without resorting to burning and re-welding. The rugged frame is protected by thick Hardox plates which are easily replaced. This goes to ensure that the FAE hybrid drums are available for many seasons and provide thousands of hours of work in the lifetime as is proven.

FAE are producing professional machines supplied around the world. Based in Fondo, Sud Tirol - Northern Italy.

FAE are manufacturing attachments for Tractors, Excavators and self propelled power units. These machines are seen working in the Construction, Forestry and Land clearing markets.

Continental Soil Technology are proud to be responsible for the Construction range of FAE machinery which centres on material processing and Soil Stabilisation. We are the construction dealers handling FAE throughout the UK and Ireland.

With some 20 years of experience in the market we are best placed to be able to offer our customers a level of dedicated support.

With some 20 years of experience in the market we are best placed to be able to offer our customers a level of dedicated support.

Parts and technical support is only phone call away.

In-depth product knowledge and extensive experience as to its application means we are assisting all our customers with the technical aspects of getting the most out of the machinery we supply. This extends to assisting in the practical on site issues with the use of various binders matrixes and how to adopt the various regulatory frameworks for best results.

As a dedicated team we are able to offer personal service and a level of support and experience that is not available through larger multi-nationals.

As a dedicated team we are able to offer personal service and a level of support and experience that is not available through larger multi-nationals.

We aim to ensure that our customers are prospering in what is often a new venture. Our customers continuing success is the best advertising available to us.

Models

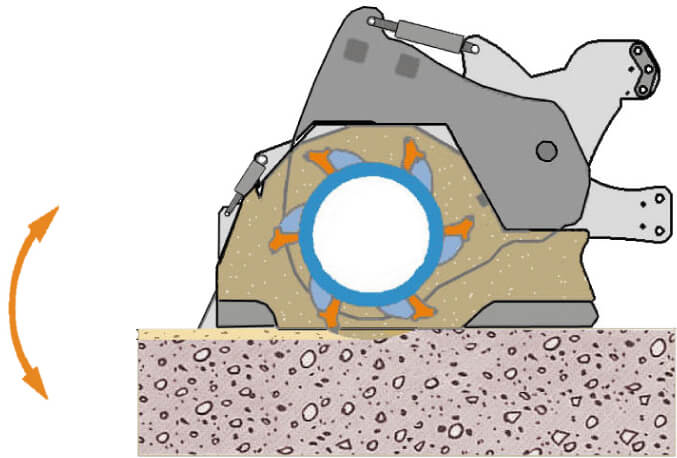

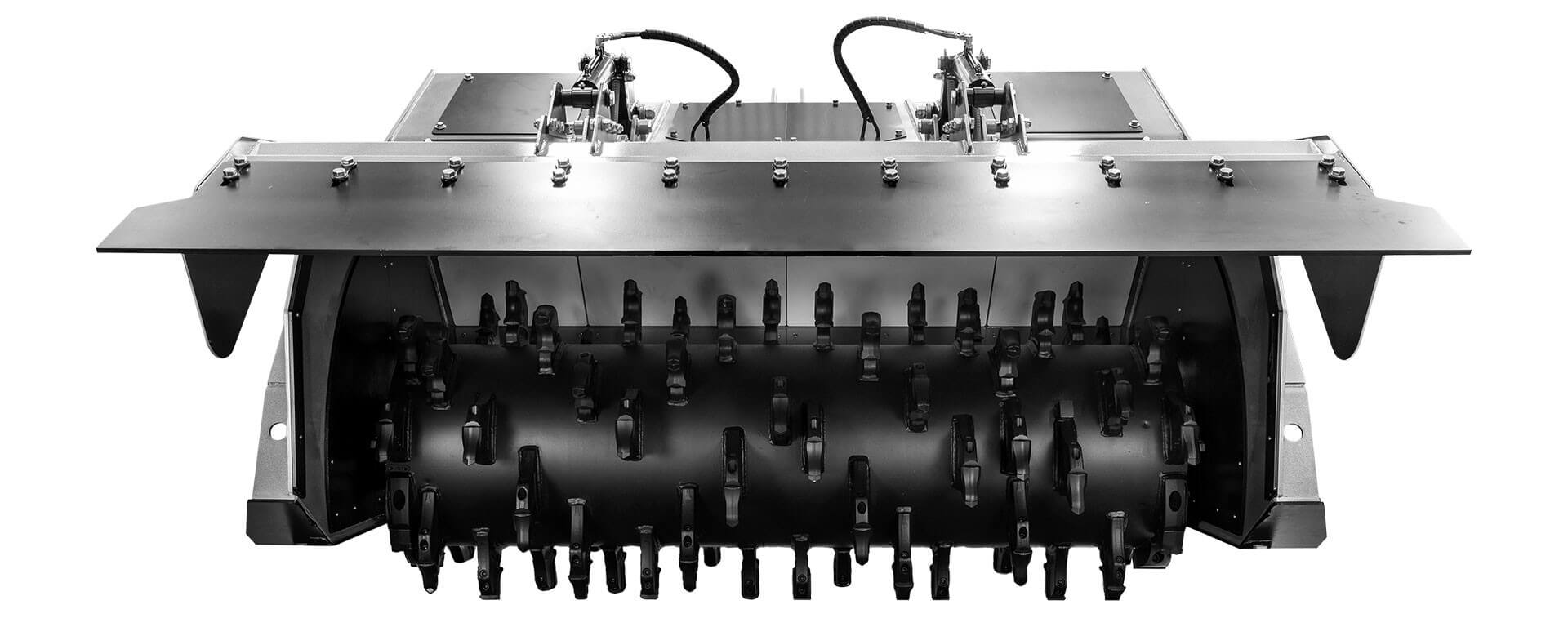

MT Multi Task Stabilisation Drums- Variable Chamber & Mobile Rotor

The Multitask range lives up to its name and is designed to be able to perform as a stone crusher, road recycler and soil stabilisation drum.

The Multi Task range features a heavy duty construction with large diameter drum, rugged gearbox drives and variable chamber mixing design.

These features facilitate crushing rocks and stones whilst mixing in a binder to a controlled depth.

The high density of rugged G3 tools gives the power to crush and also ensures a quality mixing and pulverisation.

Working depths of up to 500mm are achieved.

Soil Stabilisation High Output Drums

Where outright performance without compromise is needed the Stabi ranges come to the fore.

Maintaining the mobile rotor and variable drum concept in the Stabi and offering a cost effective fixed rotor in the Stabi FR there is a unit to suit all users.

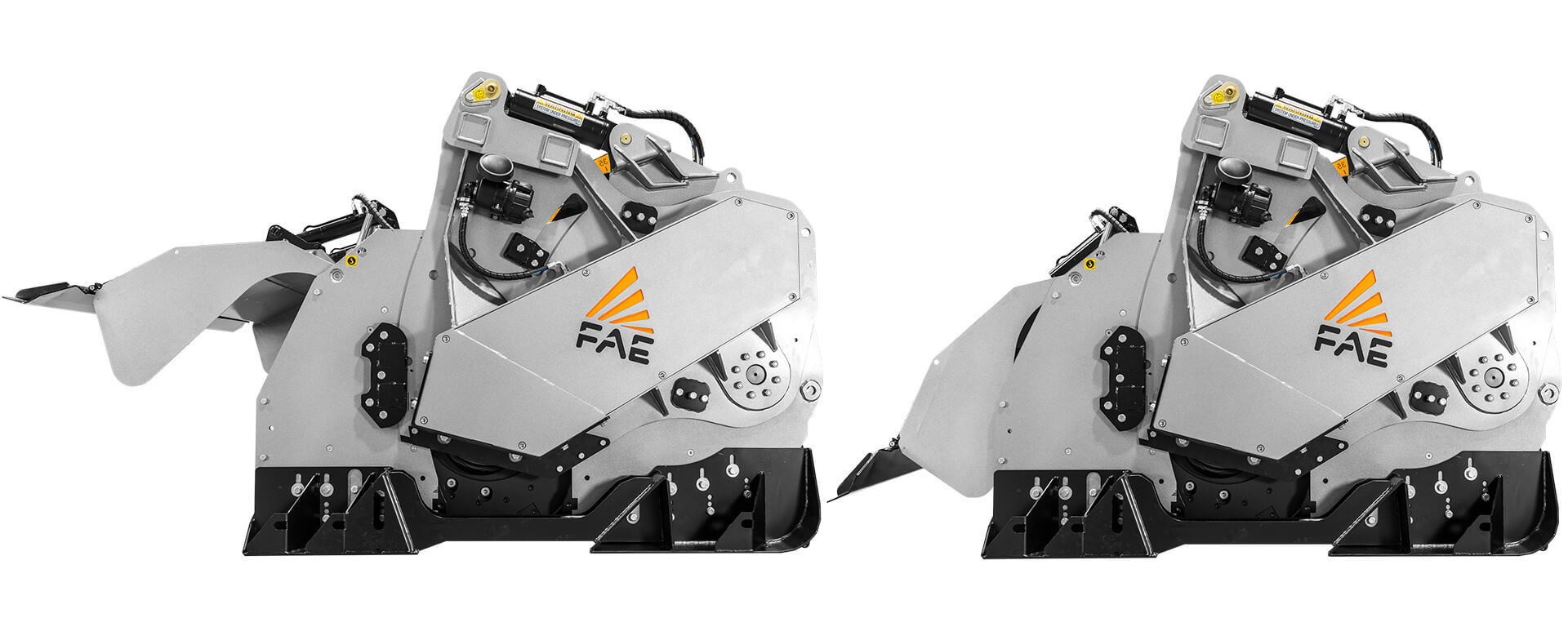

RSL Compact Crusher Stabiliser Drums

A simple compact crusher stabiliser unit the RSL offers users great adaptability and performance.

The compact nature of the fixed drum unit means the RSL performs well in rural road recycling, Forestry roads, and smaller stabilisation sites.

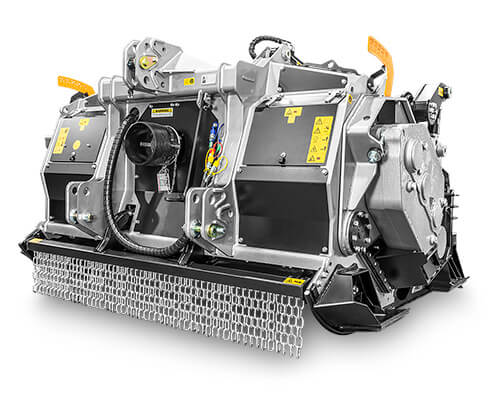

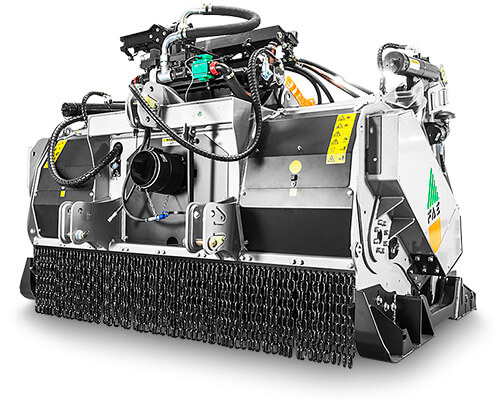

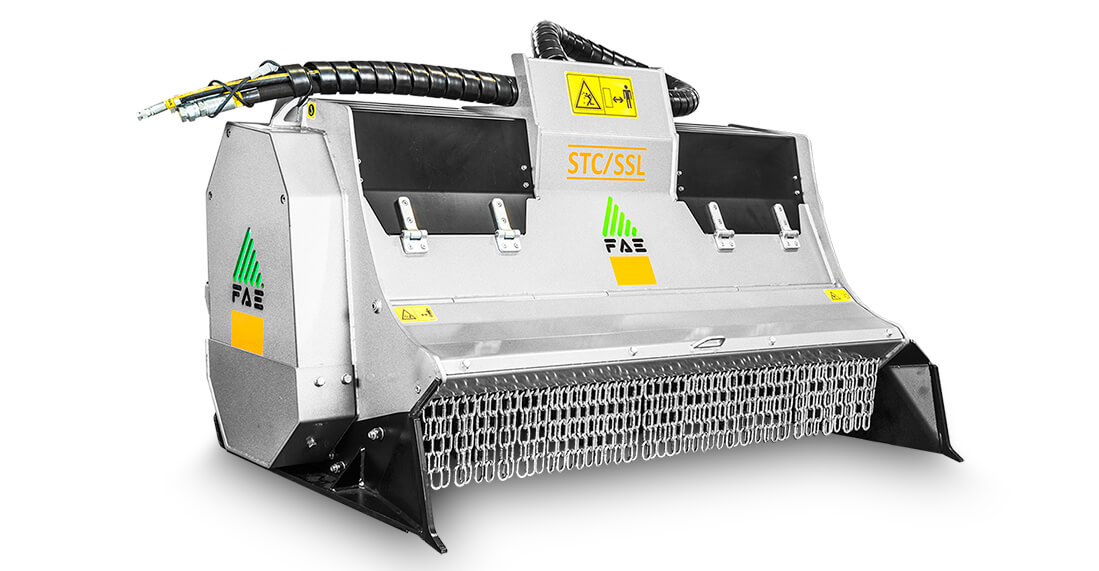

Skid Steer Crusher Stabiliser Drums

Increasing the adoption of stabilisation techniques on smaller sites needs a compact unit to process material.

The Skid Steer mounted STC SSL unit offers such an adaptable unit.

High flow hydraulics provide the power to crush and mix.

Hydraulic flow dividers are employed to facilitate controlling multiple circuits without the need to fit complicated systems onto the skid steer. A choice of electrical connections facilitates seamless integration with the skid steer and use of joystick controls and high flow power modes.